Laboratory Coal Analyser WILPO L 241

Purpose of the analyzer

The WILPO L 241 Analyser is designed for rapid determination of basic coal quality parameters (ash [Ar], moisture [Wtr] and sulphur [Str] and immediate determination of the calorific value [Qri] in technical coal samples (in working condition).

The design of the unit and original, patented measurement methods enable the analyser to be used in laboratories in mines, power plants, heat generating plants, coke plants, and also in on-site testing laboratories, storage yards, etc.

Our most recent development among analysers, the WILPO L 241, can measure four basic coal quality parameters with higher accuracy than WILPO L 132 / L 142 analysers and eliminate or minimize the impact of chemical composition variability of coal on measurement results.

General structure and principle of operation

The WILPO L 241 Analyser is designed as a single-module unit, which enables its easy use in any place.

The measurement vessel with the coal (or e.g. biomass) sample, upon placing it on the loader, is positioned precisely between probes in the measurement paths. During measurement the vessel is slowly rotated so that the entire sample is shifted many times between the probes. The sample is exposed to gamma rays, X-rays and microwaves and the measurement signals (electric pulses) from respective measurement paths are relayed to the control and measurement module, where they are counted and processed. Results of every measurement, along with additional information entered from the keyboard, such as sample number, coal buyer, etc., appear on the display and are automatically saved in computer memory.

The database that is created enables printing out of results as required by the user, e.g. results from a period of one month for coal sent to a selected buyer or provided by a selected supplier, results for samples analysed during one day with daily mean values of coal quality parameters, etc. The latest probes, electronic large-scale integration components and a fast computer system with printer provide reliable and accurate operation, as well as comfort of use.

.

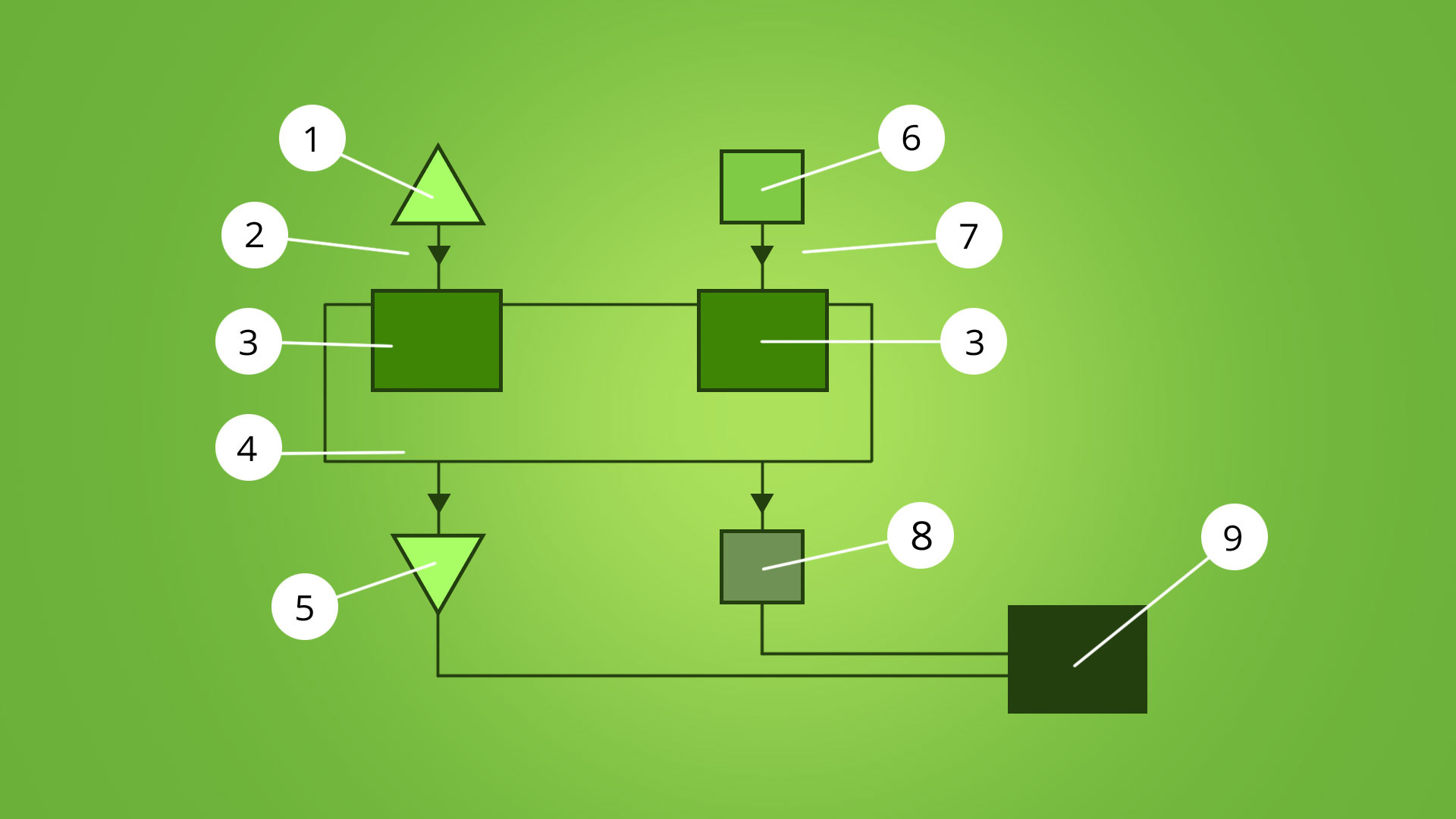

Fig. 1 shows a simplified diagram of the analyzer, where:

- 1 and 5 – transmitting and receiving microwave antennas

- 2 – microwave radiation beam

- 3 – coal sample

- 4 – rotating measuring vessel

- 6 – container with radiation source and target positioning system

- 7 – X- and gamma-ray beam

- 8 – ionizing radiation detector

- 9 – control and measurement module

Analyzer operation

Construction

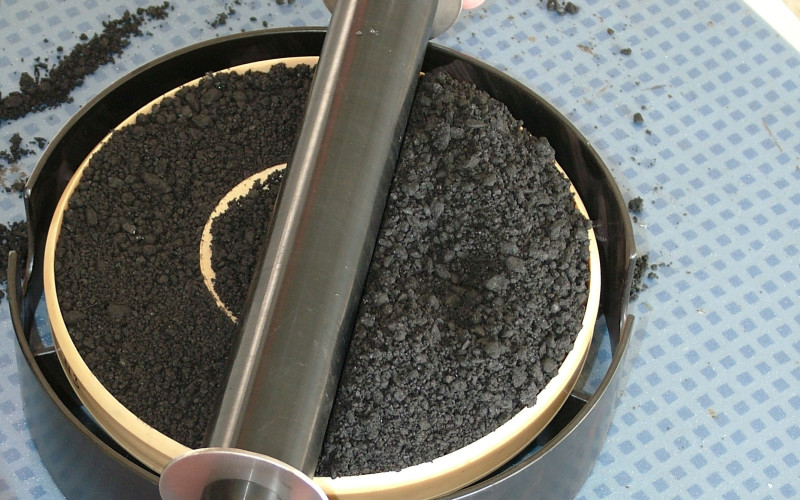

A ca. 1 kg sample, in as-is condition, is poured into a crusher (preferably a roll crusher, e.g. LAB-08-240), where it is comminuted. Afterwards the coal sample comminuted to grain size 0 to 6 mm is poured, without weighing and drying, to the measurement vessel and the top surface of coal is levelled with the roller, which is part of instrument equipment (the measurement method applied eliminates the effect of sample packing on measurement results). The sample is levelled with the roller in order to ensure complete filling of the vessel and thereby to ensure proper measurement.

Measurement implementation:

Operational safety

The Analyser is an isotopic instrument with a low-energy gamma radiation source. The design of the instrument ensures complete safety of its operation.

Its manufacture has been approved by the State Atomic Energy Agency in Warsaw (permit no. D-14478 of 11.09.2002, annex no. 1 of 2.02.2006).

Basic technical data

| Measuring material: | hard and brown coal, coal waste, ashes (combustible parts), biomass |

| Coal sample granulation: | approx. 0 – 6 mm |

| Weight of the measurement sample: | 0.4 – 0.7 kg depending on the type of coal, ash content and degree of packing, without the need to weigh |

| Sample preparation time: | approx. 100 pp |

| Measurement time | 200 s |

| Ash and sulphur determination method | absorption of gamma and X-rays |

| Radiation source: | Am-241 isotope, activity ca. 4 GBq, in a protective container of special design |

| Moisture content measurement method: | absorption of microwave radiation |

| Characteristics of microwave radiation: | frequency ~9.35 GHz power: approx. 1 mW |

Measurement accuracies defined as average, absolute values, depending on the type of coal and measurement range

|

VALUE MEASURED |

COAL TYPE AND RANGE OF VARIATION OF MEASURED VALUE |

MEASUREMENT ERROR σ |

|

Ash content Ar |

Thick assortments and some rinsed assortments 2 – 10% pop. Some assortments were washed and had raw ash content of 10 – 25%. |

0,5 – 0,7 % 0,5 – 1,0 % |

|

They had raw – 15 – 35% ash content |

0,7 – 1,0 % |

|

|

Overgrowths and waste – 25 – 50% ash content |

1,0 – 1,5 % |

|

|

Waste and stone – 50 – 85% ash content |

1,5 – 2,0 % |

|

|

Moisture content Wtr |

Range 2 – 10% moisture content |

0,5 – 0,7 % |

|

Range 10 – 25% moisture content |

0,7 – 1,0 % |

|

|

S sulfur contenttr |

Range 0.2 – 1.0% sulfur content |

0,05 – 0,10% |

|

Range 0.5 – 1.5% sulfur content |

0,1 – 0,15% |

|

|

Range 1.0 – 3.0% sulfur content |

0,1 – 0,2% |

|

|

Calorific value Qir |

Complete range |

100 – 500 kJ/kg |

|

Combustibles content |

Complete range |

ok. 0,5 % |

Dimensions of the analyzer module: 1000 x 800 x 1550 mm

Weight: approximately 95 kg

Power supply: 230V (±10%), 50 Hz